The space industry stands at a critical crossroads as it grapples with an increasingly urgent sustainability crisis. For decades, humanity's ventures beyond Earth's atmosphere have followed a fundamentally wasteful model—rockets burn through massive quantities of propellant, satellites become orbital debris at the end of their operational lives, and valuable materials are lost forever in the vacuum of space or destroyed during atmospheric reentry. Now, a groundbreaking study published in the journal Chem Circularity proposes a radical reimagining of how we approach spaceflight: applying the same circular economy principles that have transformed industries on Earth to the entire lifecycle of spacecraft and satellites.

Led by Dr. Zhilin Yang from the University of Surrey's Faculty of Engineering and Physical Sciences, an international team of sustainability and space scientists has outlined a comprehensive framework for transforming the space sector from its current linear, wasteful model to a circular space economy. Their research, titled "Resource and material efficiency in the circular space economy," addresses the mounting environmental and orbital sustainability challenges that threaten the long-term viability of space operations. The team includes Associate Professor Lirong Liu from Surrey's Center for Environment and Sustainability, Dr. Lei Xing from the University of Manitoba's Biological Sciences department, Professor Jin Xuan (Associate Dean of Research and Innovation at Surrey), and Adam Amara, Chief Scientist with the UK Space Agency and Director of the Surrey Space Institute.

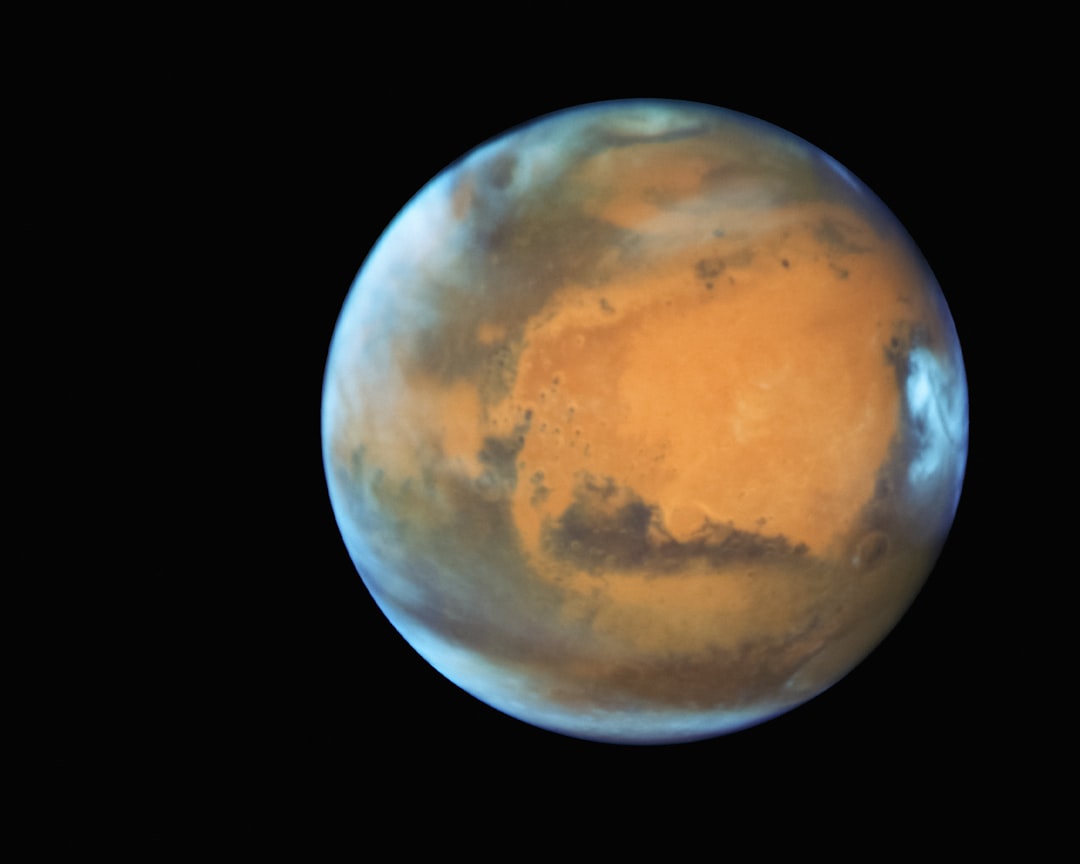

The urgency of this transition cannot be overstated. Since the Soviet Union launched Sputnik I in 1957—ushering in the space age—the world has witnessed no fewer than 7,070 successful orbital launches. This relentless expansion has created what scientists now recognize as an unsustainable orbital environment, particularly in Low Earth Orbit (LEO), where approximately 15,100 metric tons of debris now circles our planet. This debris field ranges from defunct satellites and spent rocket stages measuring several meters across to paint flecks and metal fragments just millimeters in size, all traveling at velocities exceeding 28,000 kilometers per hour.

The Growing Crisis in Earth's Orbital Environment

The proliferation of space debris represents more than just a cleanup challenge—it poses an existential threat to future space operations through what scientists call the Kessler Syndrome. Named after NASA scientist Donald Kessler who first described the phenomenon in 1978, this cascading collision scenario occurs when the density of objects in orbit reaches a critical threshold. At this point, collisions between objects generate additional debris fragments, which in turn collide with other objects, creating an exponentially accelerating chain reaction of destruction. The resulting debris field could render certain orbital altitudes unusable for generations, effectively imprisoning humanity on Earth.

The parallels to Earth's environmental challenges are striking. Just as our reliance on single-use plastics has created massive pollution problems like the Great Pacific Garbage Patch—a swirling vortex of plastic debris twice the size of Texas—our approach to spaceflight has created an orbital garbage patch that threatens the very infrastructure modern society depends upon. From GPS navigation and weather forecasting to telecommunications and Earth observation, countless essential services rely on satellites operating in the increasingly crowded orbital environment.

The environmental impact extends beyond orbital debris. Each rocket launch injects significant quantities of greenhouse gases into the upper atmosphere, including carbon dioxide, water vapor, and black carbon particles. Additionally, certain propellants release ozone-depleting chemicals into the stratosphere, where they can persist and cause disproportionate environmental damage compared to ground-level emissions. As commercial launch services proliferate and companies like SpaceX, Amazon, and OneWeb deploy mega-constellations comprising thousands of satellites, the cumulative environmental impact threatens to accelerate dramatically.

Reimagining Spacecraft Design: The Reduce Strategy

The first pillar of the circular space economy framework focuses on waste reduction through fundamental changes in how spacecraft and satellites are designed, manufactured, and operated. Drawing inspiration from the electronics and automotive industries, which have made significant strides in extending product lifespans and reducing material waste, the research team proposes several transformative approaches.

Central to the reduction strategy is the concept of modular spacecraft design. Rather than building satellites as monolithic, single-purpose units destined for disposal after their primary mission concludes, engineers could create modular platforms with standardized interfaces allowing components to be upgraded, repaired, or replaced in orbit. This approach mirrors the evolution of personal computers from sealed, proprietary systems to modular architectures with standardized components that users can upgrade individually.

"Each rocket launch sends tonnes of valuable materials into space that are never recovered," explains Professor Jin Xuan. "To make the space economy truly sustainable, we need to build circular thinking into missions from the very start—from how we design and manufacture spacecraft to how we operate and retire them. That means developing systems that can be refueled, repaired, or reconfigured in orbit, and materials that can be recovered and recycled rather than lost."

The reduction strategy also emphasizes mission consolidation—accomplishing more with fewer launches. By establishing orbital infrastructure such as refueling depots and maintenance platforms, spacecraft could extend their operational lives indefinitely, dramatically reducing the number of replacement launches required. NASA's Space Technology Mission Directorate has been pioneering this approach through initiatives like the On-orbit Servicing, Assembly, and Manufacturing (OSAM) program, which aims to demonstrate robotic satellite servicing capabilities in orbit.

Reuse and Repurposing: Extending Spacecraft Lifespans

The second pillar addresses the challenge of reusability across multiple scales, from individual components to entire spacecraft systems. This strategy draws heavily from the aerospace industry's recent successes with reusable launch vehicles, exemplified by SpaceX's Falcon 9 rocket, which has demonstrated that first-stage boosters can be recovered and reflown dozens of times, dramatically reducing launch costs and environmental impact.

However, the research team's vision extends far beyond reusable rockets. They propose developing in-orbit servicing capabilities that would allow robotic spacecraft to refuel satellites, replace degraded components, and upgrade outdated systems without requiring satellites to return to Earth. Several commercial ventures are already working toward this goal. Orbit Fab, a Colorado-based startup, is developing orbital refueling infrastructure it calls "Gas Stations in Space," while companies like Northrop Grumman have already demonstrated satellite life-extension services with their Mission Extension Vehicle (MEV) spacecraft.

Perhaps most ambitiously, the researchers advocate for developing soft-landing systems that would allow even large space stations to be safely returned to Earth at the end of their operational lives. Using advanced heat shields, parachutes, and airbag systems, these facilities could be recovered intact rather than deliberately destroyed during atmospheric reentry. This would enable the recovery of valuable materials, scientific equipment, and structural components for refurbishment and reuse in future missions—though such systems would require rigorous safety protocols to ensure controlled deorbiting and landing.

The Role of Artificial Intelligence in Sustainable Space Operations

Emerging artificial intelligence technologies will play a crucial role in enabling the circular space economy. Machine learning algorithms can analyze vast datasets from operational spacecraft to predict component failures before they occur, enabling preventive maintenance that extends mission lifespans. Digital twin simulations—virtual replicas of physical spacecraft that mirror their real-world counterparts in real-time—can reduce the need for costly physical testing during the design phase while optimizing operational efficiency throughout a spacecraft's life.

AI systems can also optimize orbital logistics, determining the most efficient routes and methods for servicing spacecraft, recovering debris, and transporting materials between orbital facilities. As the complexity of space operations increases with the deployment of mega-constellations and the establishment of orbital infrastructure, such optimization will become increasingly critical for maintaining sustainable operations.

Recycling in Space: Closing the Loop on Materials

The third pillar of the circular space economy addresses perhaps the most challenging aspect: materials recycling in the space environment. This requires developing entirely new capabilities for capturing orbital debris, processing materials in microgravity, and manufacturing new components from recycled feedstock.

Several organizations are developing active debris removal technologies capable of capturing defunct satellites and large debris fragments. These systems employ various capture mechanisms, including nets, harpoons, robotic arms, and even electromagnetic tethers. The European Space Agency's Clean Space initiative has been at the forefront of these efforts, planning missions to demonstrate debris removal technologies in the coming years.

However, the research team envisions going beyond mere debris removal to establish orbital recycling facilities where recovered materials could be processed and transformed into useful products. Metals from defunct satellites could be melted and reformed into structural components, while solar panels could be disassembled and their constituent materials separated for reuse. Electronic components could be harvested for precious metals like gold, silver, and rare earth elements—materials that are expensive and environmentally damaging to mine on Earth.

This vision aligns with emerging concepts of in-space manufacturing, where the unique properties of microgravity enable the production of materials and structures impossible to create on Earth. By combining recycling with advanced manufacturing techniques such as 3D printing, orbital facilities could become largely self-sufficient, dramatically reducing the need to launch raw materials from Earth's deep gravity well.

Learning from Terrestrial Industries

The research team emphasizes that the space sector need not reinvent the wheel when implementing circular economy principles. Several Earth-based industries have already made significant progress in addressing sustainability challenges and offer valuable lessons for space operations.

The electronics industry has developed sophisticated processes for recovering precious metals from electronic waste through urban mining—extracting valuable materials from discarded devices. These techniques could be adapted for processing defunct satellites, which contain significant quantities of valuable materials. Similarly, the automotive sector has demonstrated that remanufacturing components can extend vehicle lifespans while reducing resource consumption and waste generation. These same principles apply directly to spacecraft components, many of which could be refurbished and reused multiple times.

The sanitation industry pioneered the "reduce, reuse, recycle" framework that now serves as the foundation for waste management worldwide. By applying these same 3Rs principles to space operations from the earliest design stages, the space sector can avoid repeating the mistakes that led to Earth's current waste management challenges.

Policy Frameworks and International Cooperation

Technical solutions alone cannot achieve a sustainable space economy. The research team emphasizes the critical need for international cooperation and policy frameworks that incentivize sustainable practices and discourage wasteful approaches. Currently, space activities are governed by treaties dating back to the 1960s that never anticipated today's commercial space boom or the sustainability challenges it creates.

"We need innovation at every level, from materials that can be reused or recycled in orbit and modular spacecraft that can be upgraded instead of discarded, to data systems that track how hardware ages in space," Professor Xuan emphasizes. "But just as importantly, we need international collaboration and policy frameworks to encourage reuse and recovery beyond Earth. The next phase is about connecting chemistry, design, and governance to turn sustainability into the default model for space."

Potential policy measures could include requiring end-of-life disposal plans for all satellites before launch approval, establishing fees or deposits that incentivize satellite recovery and recycling, and creating international standards for modular spacecraft design that facilitate repair and refurbishment. Some experts have even proposed extending producer responsibility concepts to space operations, making satellite manufacturers and operators financially responsible for the entire lifecycle of their spacecraft, including disposal or recycling.

The Path Forward: Challenges and Opportunities

Transitioning to a circular space economy presents formidable technical, economic, and regulatory challenges. Developing robotic systems capable of servicing, repairing, and recycling spacecraft in the harsh space environment requires breakthroughs in autonomous robotics, materials science, and manufacturing technologies. The economics of orbital infrastructure remain uncertain, with high upfront costs that may deter investment despite long-term benefits.

Nevertheless, the potential rewards justify the effort. A sustainable space economy could dramatically reduce launch costs, extend satellite lifespans, and minimize environmental impacts while creating entirely new industries focused on orbital services and manufacturing. As humanity's presence in space expands—with plans for lunar bases, Mars missions, and space tourism—establishing sustainable practices now will prove far easier than attempting to remediate problems later.

The research team's comprehensive framework provides a roadmap for this transformation, but success will require coordinated action from governments, commercial space companies, and international organizations. The window for action is narrowing as orbital congestion increases and debris accumulation accelerates. By embracing circular economy principles today, the space industry can ensure that humanity's expansion beyond Earth remains sustainable for generations to come.

As commercial space activities continue their exponential growth, with launch rates projected to increase dramatically in the coming decades, the choice facing the space sector is clear: continue down the path of wasteful, linear operations and risk rendering space inaccessible, or embrace the circular economy principles that can ensure sustainable access to space for centuries to come. The technology, knowledge, and economic incentives exist to make this transition—what remains is the collective will to implement these changes before the orbital environment reaches an irreversible tipping point.